TUBE FITTINGS / FERRULE FITTINGS / INSTRUMENTATION COMPRESSION TUBE FITTINGS

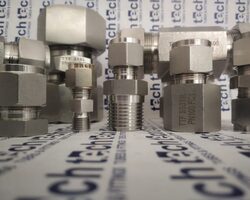

Supplier, Exporters, and Manufacturers of Ferrule Tube Fittings / Compression Tube Fittings / Ferrule Fittings / Tube Fittings and products like Male Connector, Male Adapter, Female Adapter, Bulkhead Connectors, Bulkhead Union, Tube Connectors, Ferrules, Instrumentation Tube Fittings, Tube Cap, Union Cross, High-Pressure Tube Fittings, 10000PSI Ferrule Tube Fittings, 6000PSI Ferrule Tube Fittings, Stainless Steel Compression Fittings, Female Connector, Stainless Steel Tube Fittings, Super Duplex Tube Fittings, Stainless Steel Tube Reducer, Swagelok Equivalent Tube Fittings in Mumbai, India.

Available Products in Tube Fittings

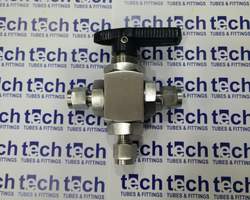

Ferrule Fittings Compression Fittings also are known as Ferrule Tube Fittings, Double Ferrule Fittings, or Single Ferrule Fittings and exported worldwide from Tech Tubes & Fittings India. High-Quality, Stringent testing procedures, airworthy or seaworthy packing, On-time delivery, full support in urgency, and economical prices give Tech Tubes & Fittings an upper hand over other industry competitors.

Type Of Stainless Steel Tube Fittings?

Stainless Steel Tube Fittings are designed as Leak Free Connections For Process, Power & Instrumentation Applications. Stainless Steel Tube Fittings are used for is a Leak Tight Seal In Process, Power, & Instrumentation Applications. Stainless Steel Tube Fittings Are Manufactured In Both Double Ferrule & Single Ferrule Design. The Stainless Steel Tube To Union Fittings are Manufactured With A Silver Plated Nut Which Extends The Life Of The Fitting, & Prevents Any Risk Of Galling.

Choose from Stainless Steel Union Fittings, Stainless Steel Union Elbow, Stainless Steel Bulkhead Union, Stainless Steel Reducing Union, Cam & Groove Hose Couplings, & More in a Wide Range Of Styles & Sizes. Stainless Steel Push to Connect Tube Fittings are manufactured to meet the specifications Required For A Wide Range Of Applications in the Hydraulic, Chemical Industry Etc.

Stainless Steel Tube Fittings are equivalent to Stainless Steel Tube Fittings & Stainless Steel Tube Fittings. We Offer A Wide Selection Of Stainless Steel Instrument Tube Fittings & Tube Adapters To Match All Types & Varieties Of Industrial Needs. Stainless Steel Tube Fittings & Stainless Steel Quick-Clamp Tube Fittings Come In A Wide Range Of Shapes And Types Including, Stainless Steel Tube Fittings Shapes Male And Female Connectors, Adapters, Reducers Tube Union, Unions, Elbows, Tees, Crosses, Caps, Plugs, And Bulkhead Fittings.

Stainless Steel are designed as Leak Free Connections For Process, Power & Instrumentation Applications. Stainless Steel Tube Fittings are used for is a Leak Tight Seal In Process, Power, & Instrumentation Applications. Stainless Steel Tube Fittings Are Manufactured In Both Double Ferrule & Single Ferrule Design. The Stainless Steel Tube To Union Fittings are Manufactured With A Silver Plated Nut Which Extends The Life Of The Fitting, & Prevents Any Risk Of Galling.

If you need to join two or more sections of the tube in fluid handling systems, the tube connectors and compression tube fittings are precisely what you need to get the job done. The purpose of the components is to ensure that the fluid system has a secure and leak-free connection and is able to withstand high pressure and temperature.

The tube connector works by creating a tight seal with its male and female components, whereas the compression tube fittings have a mechanism that creates a tight seal between tubing and fitting. Both of these components do their job masterfully. And if you are looking to get your hands on them, then Test Tubes & Fittings is undoubtedly the best place you could have landed.

We offer a wide range of components to our clients. You need to scroll through our site and request a quote for what you need.

TUBE FITTINGS

TUBE FITTINGS

All You Need to Know About Tube Fittings: A Comprehensive Guide

Introduction: Tube fittings play a crucial role in various industries, providing secure and reliable connections for fluid and gas systems. Whether you are involved in plumbing, manufacturing, or any industry that requires fluid transfer, understanding tube fittings is essential. In this comprehensive guide, we will delve into the world of tube fittings, exploring their types, applications, advantages, and key considerations. Read on to expand your knowledge on this vital component of fluid systems.

Section 1: What are Tube Fittings? Tube fittings are mechanical components used to connect, terminate, or regulate fluid flow in tubing systems. They are designed to create leak-proof connections and maintain the integrity of fluid or gas transfer. Tube fittings come in different configurations and materials to suit various applications and environments.

Section 2: Types of Tube Fittings

- Compression Fittings: Compression fittings are widely used for their simplicity and effectiveness. They consist of a nut, a ferrule, and a body that compresses the ferrule onto the tubing, creating a tight seal.

- Flare Fittings: Flare fittings utilize a cone-shaped connection to achieve a reliable seal. They are commonly used in applications that require high pressure and resistance to vibration.

- Push-to-Connect Fittings: These fittings provide quick and easy assembly without the need for special tools or expertise. They feature a push-in mechanism that securely holds the tubing in place.

- Barbed Fittings: Barbed fittings have barbs or ridges on their surface, allowing the tubing to slide over them and create a secure connection. They are commonly used in low-pressure applications.

Section 3: Applications of Tube Fittings Tube fittings find application in various industries, including:

- Plumbing and HVAC systems

- Pneumatic and hydraulic systems

- Oil and gas industry

- Chemical processing

- Food and beverage industry

- Pharmaceutical and biotech industry

- Automotive and transportation

Section 4: Advantages of Tube Fittings

- Leak-Free Connections: Tube fittings offer secure and leak-free connections, ensuring the integrity of fluid or gas transfer.

- Versatility: With a wide range of fittings available, they can accommodate different tubing sizes, materials, and connection methods.

- Easy Installation: Many tube fittings, such as push-to-connect fittings, allow for quick and hassle-free installation, saving time and effort.

- Durable and Reliable: Tube fittings are designed to withstand high pressures, temperature variations, and harsh environments, ensuring long-term performance.

Section 5: Key Considerations for Tube Fittings When selecting tube fittings, consider the following factors:

- Compatibility with tubing material and fluid/gas being transferred

- Pressure and temperature ratings

- Connection method and ease of installation

- Environmental factors (corrosion resistance, UV resistance, etc.)

- Compliance with industry standards and regulations

Conclusion: Tube fittings are vital components in fluid and gas systems, providing secure connections and efficient flow control. Understanding the different types, applications, advantages, and key considerations of tube fittings empowers you to make informed decisions for your specific needs. Whether it's a plumbing project, industrial application, or any fluid system requirement, choosing the right tube fittings ensures reliable performance and peace of mind.

Remember, proper installation and maintenance of tube fittings are crucial for optimal performance and safety. Consult with professionals or trusted suppliers for expert advice and quality fittings tailored to your requirements.

Cities

Visakhapattnam, Unnao, Indore, Surat, Pune, Chennai, Bhilai, Nagpur, Delhi, Faridabad, Chandigarh, Kanpur, Nashik, Coimbatore, Bangeluru, Jamshedpur, Vadodara, Jaipur, Udaipur, Bokaro, Pithampur, Noida, Ludhiana, Durgapur, Mysore, Moradabad, Aurangabad, Navi Mumbai, Thane, Kharagpur, Kolhapur, Ratnagiri, Belgaum, Rourkela, Panipat, Ichalkaranji, Ahmedabad, Hyderabad, Sri City, Hospet, Rudrapur, Raigarh, Aluva, Vijaywada, Firozabad, Belagavi, Bharuch, Thiruvananthpuram, Ankleshwar, Gajraula, Margao, Hosur, Gurugram, Pimpri, Chinchwad, Meerut, Morbi,

Barcelona, Chicago, Texas, Houston, Detroit, Osaka, Randstad, San Jose, Sao Paulo, Seoul, Singapore, Tokyo, Toronto, Al Jubail, Dubai, Sharjah, Abu Dhabi, Edmonton, Nevada, Rotterdam, Illinois, California, Cleveland, Moscow, Riyadh, Muscat, Bahrain, Leduc, Arlington, Tulsa, KAEC, Reno, Yanbu, Ontario, St. Lawrence Valley, Silesia, Kuzbass, Tartu, Ponferreda, Plovdiv, Asti, Atarfe, Istanbul, Los Angeles, Ho Chi Minh City, Bogota, Hanoi, Hong Kong, Montreal, Manama, Brisbane, Tehran, Baku, Kuala Lumpur, Rio de Janerio, Johannesburg, Mexico City, Milan, Ankara, Doha, Al Khobar, Ulsan, Jakarta, Santiago, Madrid, Dammam, Dhaka, Manila, Lima, Lagos, St Petersburg, Abidjan, Dar Es Salaam, Jeddah, Alexandria, Yokohama, Guayaquil, Algiers, Kano, Nairobi, Incheon, Brasilia, Salvador, Kiev, Buenos Aires, Rome, Taipei, Osaka, Chittagong, Daegu, Bursa, Accra, Guatamala, Bucharest, Cordoba, Melbourne, Sydney, Vienna, Ganja, Brussels, Sofia, Havana, Helsinki, Tbilisi, Hamburg, Athens, Debrecen, Dublin, Cork, Tel Aviv, Jerusalem, Ammam, Auckland, Oslo, Begen, Lisbon, Porto,

Durban, Cape Town, Stockholm, Gothenburg, Kampala, Kyiv, Birmingham,

Ferule Tube Fittings

EXPORTS

We have built strong relationships and exports all over the world in countries like

Denmark, Costa Rica, Croatia, Cuba, Ecuador, Egypt, Estonia, Fiji, Finland, Georgia, Germany, Ghana, United Kingdom (UK), Greece, Guatemala, Hungary, Iceland, Indonesia, Iran, Iraq, Italy, Israel, Japan, Jordan, Kazakhsthan, Kenya, Paraguay, Peru, Philippines, Poland, Portugal, Puerto Rico, Qatar, Romania, Russia, Saudi Arabia, Serbia, Singapore, Slovakia, South Africa, South Korea, Sudan, Spain, Sri Lanka, Sweden, Switzerland, Tajikistan, Tanzania, Thailand, Togo, Turkey, Turkmenistan, Uganda, Ukraine, United Arab Emirates (UAE), United States of America (USA), Uruguay, Uzbekistan, Venezuela, Vietnam, Yemen, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Liechtenstein, Lithuania, Macedonia, Malaysia, Maldives, Mali, Malta, Mauritius, Mexico, Moldova, Montenegro, Nepal, Netherlands, Nigeria, Norway, Oman, Afghanistan, Albania, Algeria, Argentina, Australia, Azerbaijan, Bahamas, Bahrain, Belarus, Belgium, Bolivia, Bosnia & Herzegovina, Brazil, Brunei, Bulgaria, Myanmar, Canada, Chile, Colombia, New Zealand, Nicaragua, Panama, Guyana, Suriname, French Guiana, Ireland, Austria, Kosovo, Slovenia, Andorra, Angola, Anguilla, Armenia, Aruba, Austria, Benin, Bolivia, Bosnia and Herzegovina, Burundi, Burkina Faso, Benin, chad, Cocos Island, Comoros, Colombia, Cuba, Cyprus, Croatia, Denmark, Dominica, Djibouti, Eritrea, Estonia, Ecuador, Finland, Fiji, Falkland Island, French Polynesia, Ghana, Gabon, The Gambia, Gibraltar, Guam, Grenada, Guyana, Guinea, Greenland, Haiti, Holy See, Honduras, Kosovo, Kyrgyzstan, Libya, Lesotho, Lithuania, Luxembourg, Latvia, Malawi, Mali, Malta, Macau, Madagascar, Maldives, Mayotte, Mauritius, Martinique, Monaco, Mongolia, Moldova, Mayotte, Mozambique, Morocco, Montserrat, Namibia, Nauru, Niger, Niue, Nigeria, Norway, Nicaragua, Northern Mariana Island, Palau.

LEGAL DISCLAIMER

|

All registered names, trademarks, copyrights and part numbers like Inconel, Monel, Hastelloy, Zeron etc., remain the property of their respective owners. All use of OEM names, part, model and item numbers are for reference and identification purposes only. TECH TUBES & FITTINGS is not an endorsed reseller or representative of any of above listed Materials / Brands or their respective products. TECH TUBES & FITTINGS products do not infringe on Trade Marks Act 1995 or Copyright Act 1968, and to the best of our knowledge and through investigation we are not in contravention of any current patents |

Tube to Union

- Union

- Reducing Union

- Bulk Head Union

- Union Elbow

- Union Tee

- Union Cross

TUBE TO MALE

- Connector

- Bulk Head Connector

- Elbow

- Run Tee

- Branch Tee

TUBE TO FEMALE

- Connector

- Bulk Head Connector

- Elbow

- Run Tee

- Branch Tee

ACCESSORIES

- Blanking Plug

- Blanking End

- Nut

- Front Ferrule

- Back Ferrule

FEATURED PRODUCTS

- SS 304L Ferrule Tube Fittings

- SS 316L Ferrule Tube Fittings

- SS 304H Ferrule Tube Fittings

- SS 316H Ferrule Tube Fittings

- Brass Ferrule Tube Fittings

- Single Ferrule Tube Fittings

- Double Ferrule Tube Fittings

- Inconel Ferrule Tube Fittings

- Incoloy Ferrule Tube Fittings

- Monel Ferrule Tube Fittings

- Inconel Ferrule Tube Fittings

- Incoloy Ferrule Tube Fittings

- Monel Ferrule Tube Fittings

- High Pressure Ferrule Tube Fittings

- High Pressure Ferrule Tube Fittings

- 6000PSI Ferrule Tube Fittings

- 10000PSI Ferrule Tube Fittings

- Duplex Ferrule Tube Fittings

- Super Duplex Ferrule Tube Fittings

- Inconel 600 Ferrule Tube Fittings

- Inconel 625 Ferrule Tube Fittings

- Inconel 800 Ferrule Tube Fittings

- Inconel 825 Ferrule Tube Fittings

- Monel 400 Ferrule Tube Fittings

- Monel K400 Ferrule Tube Fittings

- Hastelloy C276 Ferrule Tube Fittings

- Hastelloy C22 Ferrule Tube Fittings

- Hastelloy B2 Ferrule Tube Fittings

- SS 904L Ferrule Tube Fittings

- Alloy 254 Ferrule Tube Fittings

- High Pressure Tube Fittings

- 10000PSI Tube Fittings

FEATURED GRADES

- SS 304L Ferrule Tube Fittings

- SS 316L Ferrule Tube Fittings

- SS 317L Ferrule Tube Fittings

- SS 310 Ferrule Tube Fittings

- SS 904L Ferrule Tube Fittings

- Alloy 400 Ferrule Tube Fittings

- Alloy K500 Ferrule Tube Fittings

- Alloy 600 Ferrule Tube Fittings

- Alloy 625 Ferrule Tube Fittings

- Alloy 800 Ferrule Tube Fittings

- Alloy 825 Ferrule Tube Fittings

- Alloy C276 Ferrule Tube Fittings

- UNS S31803 Ferrule Tube Fittings

- UNS S32205 Ferrule Tube Fittings

- UNS S32750 Ferrule Tube Fittings

- UNS S32760 Ferrule Tube Fittings

- Brass Ferrule Tube Fittings