Flanges | Best Quality SS Tube, Pipe, Valve, Ferrule Fittings Supplier in India

Tube Fittings

> Single Ferrule Tube Fittings

> Double Ferrule Tube Fittings

Pipe Fittings

> Forged Pipe Fittings

> Barstock Pipe Fittings

> O-Lets

Flanges

> Forged Flanges

> Plate Flanges

Valves

> Needle Valves

> Manifold Valves

> Ball Valves

> Check Valves

OUR BRAND

FEATURED GRADES

- A182 F304L Flanges

- A182 F316L Flanges

- A182 F304H Flanges

- A182 F316H Flanges

- A105 Flanges

- A350 LF 2 Flanges

- Alloy K500 Flanges

- Alloy 600 Flanges

- Alloy 625 Flanges

- Alloy 800 Flanges

- Alloy 825 Flanges

- Alloy C276 Flanges

- UNS S31803 Flanges

- UNS S32205 Flanges

- UNS S32750 Flanges

- UNS S32760 Flanges

- A182 F321 Flanges

- Alloy 20 Flanges

- Alloy Steel Flanges

- Carbon Steel Flanges

- CuproNickel Flanges

- Titanium Flanges

- Super Duplex Flanges

- Duplex Pipe Flanges

- A182 F316 Flanges

- A240 Plate Flanges

- A516 Gr70 Flanges

- Duplex Forged Flanges

- Inconel Flanges

- Monel Flanges

- A182 F11 Flanges

- A182 F22 Flanges

- Hastelloy Flanges

- A182 F51 Flanges

- A182 F55 Flanges

- Titanium Flanges

- Alloy 254 Flanges

FEATURED PRODUCTS

- A182 Flanges

- Weld Neck RF Flanges

- Slip On RF Flanges

- Blind RF Flanges

- RTJ Flanges

- SORTJ Flanges

- WNRTJ Flanges

- BLRTJ Flanges

- SWRTJ Flanges

- Lap Joint Flanges

- Nipo Flanges

- Spectacle Blind Flanges

- Figure 8 Flanges

- Paddle Spaces & Blanks

- Orifice Flanges

- NPT Threaded Flanges

- Socket Weld Flanges

- ASME B16.5 Flanges

- ASME B16.36 Flanges

- ASME B16.48 Flanges

- ASME B16.48 Series A Flanges

- ASME B16.48 Series B Flanges

- JIS Flanges

- BS 10 Table D Flanges

- BS 10 Table E Flanges

- BS 10 Table F Flanges

- BS 10 Table H Flanges

- PN 10 Flanges

- PN 16 Flanges

- PN 40 Flanges

- DIN Flanges

- A182 F51 Flanges

- A182 F53 Flanges

- A182 F55 Flanges

- Duplex Steel Flanges

- Super Duplex Steel Flanges

- SS A182 F304L Flanges

- SS A182 F316L Flanges

- SS A182 F904L Flanges

- SS A182 F321 Flanges

- SS A182 F310 Flanges

- Inconel 600 Flanges

- Inconel 601 Flanges

- Inconel Flanges

- Titanium Forged Flanges

- Titanium Plate Flanges

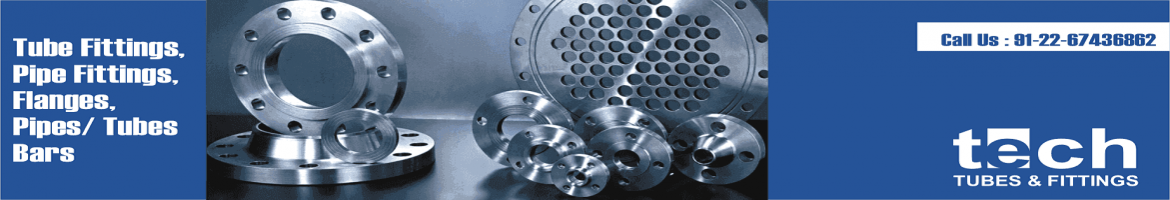

FORGED & PLATE FLANGES

- Stainless Steel Flanges, Alloy Steel Flanges, Super Duplex Steel Flanges, ASME B16.5 Flanges, Spectacle Blind Flanges, SORF Flanges, A105 Carbon Steel Flanges, Cupro Nickel Flanges, ASME B16.36 Orifice Flanges. Forged Titanium Flanges, Weld Neck Flanges

TYPE

- Forged Flange

- Plate Flange

RANGE

- Slip on, Blind, Weld Neck, Socketweld, Threaded and Lap Joint Flanges

- Orifice Flanges with Plates if needed

- RTJ (Ring Type Joint) Facing

- Rings - R Type, RX Type, BX Type

- API, MSS, AWWA

- Spectacle Blinds

- Long Weld Neck Flange

- Paddle Spaces & Blinds

SIZE RANGE

- 1/2" NB ( 15mm NB ) to 32" NB ( 800mm NB )

PRESSURE RANGE

- 75# to 2500#

DIMENSIONS in accordance with

- ASME B 16.5

- ASME B 16.47

- BS EN 1092-1

- BS 10 Table D,E,F,H

- ASME B 13.36

- ASME B 16.48

- JIS 5K, 10K

- Customer Drawing

GRADE

| Carbon Steel | ASTM A 105 /N, ASTM A 350 LF2 Class 1, ASTM A 694 F52, ASTM A 694 F60, ASTM A 694 F65, ASTM A 694 F70, MSS-SP44 F52 to F70 |

| Alloy Steel | ASTM 182 F5, ASTM 182 F9, ASTM 182 F11, ASTM 182 F22, ASTM 182 F91 |

| Stainless Steel | ASTM A 182 F304/H/L, ASTM A 182 F310/H, ASTM A 182 F316/H/L, ASTM A 182 F317/L, ASTM A 182 F321/H, ASTM A 182 F347/H/L |

| Duplex Steel | ASTM A 182 F44, ASTM A 182 F51, ASTM A 182 F60, ASTM A 182 F61 |

| High Performance Alloys |

Alloy 20, ASTM B462 A20, Alloy C276, Nickel 200/201,ASTM B730 A200/201, MONEL Alloy 400, ASTM B564 A400, Duplex 2205, ASTM A 182 2205, Duplex 2507, ASTM A 182 2507, Inconel Alloy 600, ASTM B564 A600, Inconel Alloy 625, ASTM B 564 A625, Alloy 800 HT, ASYM B564 A800HT, Incoloy Alloy 825, ASTM B564 A825 |

Inconel 625 Flanges manufacturer in India, Incoloy 800 Flanges manufacturer in India, Incoloy 825 Flanges manufacturer in India, Alloy 20 Flanges manufacturer in India, Hastelloy C22 Flanges manufacturer in India, Hastelloy C276 Flanges manufacturer in India, Monel 400 Flanges manufacturer in India,Forged Titanium Flanges Tech Tubes & Fittings is a acclaimed Titanium Forged Flange manufacturers in India which has no Minimum Order Quantity requirements

LEGAL DISCLAIMER

|

All registered names, trademarks, copyrights and part numbers like Inconel, Monel, Hastelloy, Zeron etc., remain the property of their respective owners. All use of OEM names, part, model and item numbers are for reference and identification purposes only. TECH TUBES & FITTINGS is not an endorsed reseller or representative of any of above listed Materials / Brands or their respective products. TECH TUBES & FITTINGS products do not infringe on Trade Marks Act 1995 or Copyright Act 1968, and to the best of our knowledge and through investigation we are not in contravention of any current patents |

Hastelloy Alloy C276 Flanges

Tech Tubes & Fittings provides a full line of quality Hastelloy Forged Flanges & Hastelloy Plate Flanges.These Hastelloy Flanges are manufactured with precision capabilities in accordance with ASTM, ANSI, DIN, MSS, BS, JIS, IS Standards.Monel Flanges are also manufactured as per Client's customization and drawings. Hastelloy Flanges for High Pressure, Low Pressure services. Heavy forged flanges are manufactured too. Big Diameter flanges too fall in our range of Monel Flanges.

Most sold Hastelloy Flanges : Hastelloy C276 Flanges, UNS N10276 Flanges, Alloy C276 Flanges, Hastelloy Orifice Flange, Hastelloy RTJ Flange, Alloy C276 Socket Weld Flange, Hastelloy SORF Flanges, BLRF Flanges, SWRTJ Flange, Weld Neck Flange, Hastelloy C276 Spectacle Blind Flange, Hastelloy C22 Flanges, Hastelloy X Flanges, Alloy C22 Flanges, Alloy X Flanges.

TYPE

- Hastelloy C276 Forged Flange

- Hastelloy C276 Plate Flange

RANGE

- Hastelloy C276 Slip on, Blind, Weld Neck, Socket weld, Threaded and Lap Joint Flanges

- Hastelloy C276 Orifice Flanges with Plates if needed

- Hastelloy C276 (Ring Type Joint) Facing

- Hastelloy C276 Rings - R Type, RX Type, BX Type

- Hastelloy C276 API, MSS, AWWA

- Hastelloy C276 Spectacle Blinds

- Hastelloy C276 Long Weld Neck Flange

- Hastelloy C276 Paddle Spaces & Blinds

SIZE RANGE

- 1/2" NB (15mm NB) to 32" NB (800mm NB)

PRESSURE RANGE

- 75# to 2500#

DIMENSIONS in accordance with

- ASME B 16.5 Hastelloy

- ASME B 16.47

- BS EN 1092-1

- BS 10 Table D,E,F,H

- ASME B 13.36

- ASME B 16.48

- JIS 5K, 10K

- Customer Drawing

Featured Products

Hastelloy C276 Flanges

Hastelloy C276 BLRF Flanges

Hastelloy C276 SORF Flanges

Hastelloy C276 WNRF Flanges

Hastelloy C276 Orifice Flanges

Hastelloy C276 RTJ Flanges

Hastelloy C276 Spectacle Blind Flanges

Hastelloy C276 B16.5 Flanges

Hastelloy C276 B16.47 Flanges

Hastelloy C276 B16.36 Flanges

Hastelloy C276 BS10 Table Flanges

Alloy C22 Flanges

Alloy C22 BLRF Flanges

Alloy C22 SORF Flanges

Alloy C22 WNRF Flanges

Alloy C22 Orifice Flanges

Alloy C22 RTJ Flanges

Alloy C22 Spectacle Blind Flanges

Alloy C22 B16.5 Flanges

Alloy C22 B16.47 Flanges

Alloy C22 B16.36 Flanges

Alloy C22 BS10 Talbe Flanges

These Hastelloy Flanges Are Sold To Countries Like: Denmark, Costa Rica, Croatia, Cuba, Ecuador, Egypt, Estonia, Fiji, Finland, Georgia, Germany, Ghana, United Kingdom (UK), Greece, Guatemala, Hungary, Iceland, Indonesia, Iran, Iraq, Italy, Israel, Japan, Jordan, Kazakhsthan, Kenya, Paraguay, Peru, Philippines, Poland, Portugal, Puerto Rico, Qatar, Romania, Russia, Saudi Arabia, Serbia, Singapore, Slovakia, South Africa, South Korea, Sudan, Spain, Sri Lanka, Sweden, Switzerland, Tajikistan, Tanzania, Thailand, Togo, Turkey, Turkmenistan, Uganda, Ukraine, United Arab Emirates (UAE), United States of America (USA), Uruguay, Uzbekistan, Venezuela, Vietnam, Yemen, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Liechtenstein, Lithuania, Macedonia, Malaysia, Maldives, Mali, Malta, Mauritius, Mexico, Moldova, Montenegro, Nepal, Netherlands, Nigeria, Norway, Oman, Afghanistan, Albania, Algeria, Argentina, Australia, Azerbaijan, Bahamas, Bahrain, Belarus, Belgium, Bolivia, Bosnia & Herzegovina, Brazil, Brunei, Bulgaria, Myanmar, Canada, Chile, Colombia, New Zealand, Nicaragua, Panama, Guyana, Suriname, French Guiana, Ireland, Austria, Kosovo, Slovenia

Stainless Steel Flanges

Stainless Steel Is Defined As A Steel Alloy Which Has Minimum Of 11.5% Chromium Content. Stainless Steel Does Not Corrode, Stain Or Rust As Easily As Normal Steel, But It Is Not Stain Proof. It Is Also Known As Corrosion Resistant Steel When Alloy Type & Grade Are Not Detailed, Particularly In The Aviation Industry. There Are Different Grades & Surface Finishes Of Stainless Steel To Suit The Environment To Which The Material Will Be Subjected In Its Lifetime.

Stainless Steel Flanges.

Stainless Steel Weld Neck Flanges.

Stainless Steel Blind Flanges.

Stainless Steel Flanges Provide An Easy Access For Cleaning, Inspection Or Modification. They Usually Come In Round Shapes, Square Shapes & Rectangular Shapes. These Flanges Are Joined To Each Other By Bolting & Joined To The Piping System By Welding Or Threading, Stainless Steel Flanges Which Are Used As A Plate For Covering Or Closing The End Of A Pipe Are Called As Blind Flange.

Stainless Steel API Flange Material Is To Be Considered For Its Application Prior To Ordering, This Is Due To The Structural Integrity Of The Application That The Flange Will Be Used On Currently, The Most Common Materials For Flanges Are Carbon Steel High Temperature Carbon Steel Flanges, Low Temperature Carbon Steel Flanges, High Yield Carbon Steel Flanges To Match.

Stainless Steel Exhaust Flanges Made Of Alloy Steel Include Duplex Steel & Duplex Flanges & F 53-F 55 Super Duplex Flanges. Stainless Steel Flange Fittings Made Up Of Nickel Alloys Titanium, Aluminium, Copper, Polypropylene etc.

Stainless Steel Plate Flanges Also Contains Varying Amounts Of Carbon, Silicon & Manganese. Other Elements Such As Nickel & Molybdenum May Be Added To Impart Other Useful Properties Such As Enhanced Formality & Increased Corrosion Resistance Of Flanges.

Stainless Steel Threaded Flange Can Also Be Used In Special Applications Of Slightly Chlorinated & Deserted Water & Can Be Easily Assembled Without Welding. Stainless Steel Weld Neck Flange Performs Well In Oil & Gas Applications Where Deserted & Low Hydrogen Sulfide Exist. Stainless Steel Floor Flange Operates Well In Environments Requiring Moderate Corrosion Resistance & High Mechanical Properties. Stainless Steel Flange Help To Avoid Leaks In Pipelines Where Media Is Transferred At High Pressure & High Temperature & Offers Higher Creep, Stress To Rupture & Tensile Strength At Elevated Temperatures.